3.3 STERN AND TRANSOMS

a.)Single Engine hatch wide enough to provide engine maintenance.

b.) 1 outboard swimming ladders, stainless, installed under platform.

4. ENGINE/S

a.) One single inboard mounted engine FPT 230 h.p. Stern Drive model

b.) 1 dual function single lever engine controls, Morse SL3 or similar, side mount

c.) Engine instruments set as engine supply

d.) Digital FPT instrumental panel ( Optional if requested 65000 THB )

5. ELECTRICAL EQUIPMENT

5.1 CONSUMERS

a.) Navigation lights: running lights (112.5 degree port & starboard), mounted on side; 225-degree white masthead light; 135-degree white stern light; and 360-degree white anchor. All lights – series 40 size

b.) 4 deck lights, automotive kind, corrosion resistant for exterior use. Location – above tables port and starboard, above galley, above steering console.

c.) Courtesy light on saloon

d.) 2 bilge pumps

e.) Cigarette lighter

f.) Lewmar Anchor windlass (Optional if requested 65,000 THB)

g.) Bow Thruster (Optional 78,500 THB)

h.) Saloon fans

i.) Small 5 inches Combo Navigation equipment

j.) CD-player and HI-FI system, Car type with Mic Jack and sound system to support tours.

5.2 GENERAL

a.) DC system to be isolated 2-conductor (positive/negative) with negative ground.

b.) 1 house battery, 12-volt, 4-D, 150 amp hours, car type battery,, located in service compartment, starboard.

c.) Fuse block: connect AGC fuse block before run wiring to DC panel or other panel.

d.) 1 engine starter batteries, 12-volt, 90-100 amp hours each, 4-D, 375 MCA amps, car type battery, located under instrument console, portside.

e.) Battery selector switches: (1) main DC panel on/off; (2) main-

engine-start option 1 is 1/2/both/off (blue sea 350 compact battery switch) or option 2 is on/off/both (blue sea E-series dual circuit plus battery switch).

f.) DC circuit breaker/distribution panel: kind BEP Marine 903D 12-volt or similar, 20 circuit breaker panel, with digital amp and volt meters, with main panel master on-off switch, individual circuits not be powered by more than one source at a time, each individual circuit breaker to be clearly labeled, panel to be illuminated, individual breaker, switches to glow in both on and off positions, panel labels easily readable with all other cabin lights off at night, meters to be illuminated.

g.) DC negative ground to: the DC negative bus is to be grounded to the hull at one point only. DC wiring must NOT make electrical contact with any other portion of the hull or AC wiring anywhere.

5.3 CONDUCTOR

a.) Conductors that are not sheathed shall be supported throughout their length in conduits, cable or trays, or by individual supports at maximum intervals of 300 mm.

b.) Sheathed conductors and battery conductors to the battery disconnect switch shall be supported at maximum intervals of 300 mm, with the first support not more than 1 m from the terminal. Other sheathed conductors shall be supported at maximum intervals of 450 mm.

c.) A DC circuit not contained in the same wiring system as an AC circuit.

d.) Conductors are AG10 marine grade.

e.) Conductors bigger then AG10 (i.e. battery cables) are automotive cables.

f.) For battery cable NOT use welding cable.

5.4 CIRCUIT BREAKER PANEL

a.) BEP marine model 903D or similar and amp meter for Main panel connected to main battery.

b.) Double pole breaker 50A for anchor windlass connect to engine battery.

c.)Bilge pump panel should be connected directly to main battery.

d.) All terminals to be captured-spade or ring type and are to match their respective stud size.

5.5 CHARGING SYSTEM

a.) Blue Sea Battery link ACR use to connect between house battery and engine battery or similar.

b.)Alternators for engine battery.

6. SYSTEMS

6.1 BILGE PUMPS

Bilge pumps system includes:

a.) 1 automatic bilge pumps, 500 GPH, 12V with float switches in forepeaks and in afterpeaks.

b.) 1 automatic bilge pumps, 1500 GPH, 12V with float switches in middle compartments

c.) Bilge pumps panel switches should be three-way type, with light indicator.

d.) Bilge pumps switches/indicator panel should be mounted on the steering console, easily visible.

e.) For each pump, discharge pipe of appropriate size should have a siphon loop at least 300 mm above fully loaded waterline.

f.) Each discharge outlet should have plastic or stainless seacock fitting.

g.) Bilge pumps should have separate power switch from batteries, allowing to power bilge pumps when all boat is shut down.

Bilge pumps installation should be in compliance with ISO 15083 Small craft – Bilge pumping system.

6.2 VENTILATION SYSTEM

Attention is paid to ventilation of abandoned boat at rest in order to:

a.) Prevent decay on wooden structures

b.) Remove possible fuel vapors from the bilge

c.) Ventilation is provided by:

d.) Hatches in plastic.

e.) Ventilation of forepeak and afterpeak compartments – natural, 4 ventheads (one per compartment) of flat type, 100 mm in diameter.

f.) Ventilation of fuel tank compartments (middle compartments) – natural, provided by intake and exhaust openings with total area 14000 mm2 on hull. Intake and exhaust openings to be fitted with low-profile splash proof PVC cowls.

g.) Ventilation of batteries compartment – natural

Ventilation of Refrigerator compartment – natural, via louvered vents in compartment.Ventilation system should be in compliance with ISO 11105 : 1997 Small craft – Ventilation of petrol engine and/or petrol tank compartments and ISO 10239 Small craft – Liquefied petroleum gas (LPG) systems.

6.3 AIR CON SYSTEM & REFRIGERATION

a.) Car type Air con of at least 9,000 BTU with compressor attached to engine.

b.) 6 diffusor for air connected to Air Con with 3 inches conduit

c.) House kind small refrigerator, 12 volt, on a Saloon side enough for store 6 bottle of wines-champagne

6.4 FUEL SYSTEM

Fuel system is one tank, one engine type and consists of:

a.) 1 per 200 lt fuel tank, vinyl ester fiberglass, with baffles.

b.) 1 deck fuel inlet fittings, located on the bulwark port or starboard, marked as DIESEL.

c.) Fuel filling lines, made of fuel grade hose (local manufactured), 38 mm in diameter, with 2 shut-off valves.

d.) Distribution lines, made of fuel grade hose (local manufactured), 25 mm in diameter.

e.) Tank vent pipe, made of fuel grade hose (local manufactured) 12 mm in diameter, with vent fitting.

f.) Hose clamps, made of stainless steel CrNi 18- or equivalent.

g.) 1 fuel filters/water separators.

h.) Shut-off valves, manual, available from swimming platforms, for each engine..

i.) 1 fuel gauges (senders), suitable for fuel tanks of 300 mm depth, as described above.

Fuel system installation should correspond to ISO 10088 Small craft – Permanently installed fuel systems and fixed fuel tanks.

6.5 FIRE FIGHTING SYSTEM

Fire fighting system includes:

a.) 2 fire extinguishers Kiddie Mariner 340, 5lbs of agent weight, dry-chemical type, or similar approved model. One located in galley area, another in reach from steering station.

Fire fighting system installation should correspond to ISO 9094-1 Small craft – Fire protection – Part 1: Craft with a hull length of up to and including 15m.

7. DECK EQUIPMENT AND HARDWARE

7.1 DECK HARDWARE

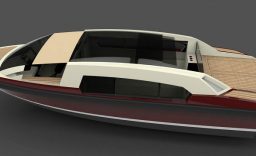

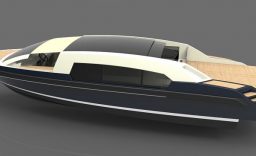

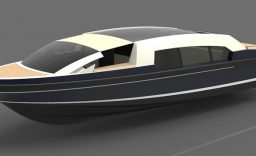

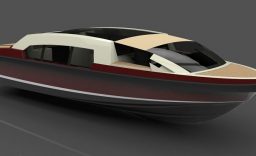

a.) Saloon roof, made of aluminum frame

b.) Roof support pillars, made in fiberglass , molded.

c.) Roof slider made in aluminum o stainless

d.) Handholds, located around roof perimeter, made of 304 or 316 stainless steel, 25 mm pipe. Included in the price above.

e.) Arch mast made of stainless pipes 304 or 316, 38 mm, foam filled, FRP coated, painted. Included in the price above.

Deck safety equipment installation should follow ISO 15085 Small craft – Man-overhead prevention and recovery.

7.2 HATCHES, PORTLIGHTS AND DOORS

a.) 1 forepeak hatch

b.) 1 afterpeak hatch – flash mounted

c.) Entrance hatch to saloon from driver cockpit composed by two sliding panels with hinged door top (front Hatch)

d.) 2 bilge access hatches – flash mounted

e.) Side windows fixed type, in acrylic, grey shaded 40%

f.) All roof build in acrylic 8 mm with a grey shaded 40% to prevent heat

– Windows, portlights and doors should comply with ISO 12216 Small craft – Windows, portlights, hatches, deadlights and doors – Strength and tightness requirements.

7.3 ANCHOR EQUIPMENT

Anchor equipment should include:

a.) Anchor of approved type, 8-10 kg (35 lbs) hot dip galvanized.

b.) Anchor roller, Windline URM-1 or similar, stainless steel.

c.) Anchor rope 30 m of 1/2” nylon rope

d.) Or instead of c) anchor chain 15 m, 1/4” hot dip galvanized, with 2 swivels and quick release link

e.) Anchor windlass Lewmar (Optional)

f.) Rope/chain locker, in front console, with hatch cover, deck pipe and drains.

7.4 MOORING AND TOWING EQUIPMENT

Mooring and towing equipment includes:

a.) 4 mooring cleats, 6”, in stainless, located on the bow and stern of each hull.

b.) 2 side fender cleats, 4 inches

c.) 3 mooring ropes of 6 m each, 12 mm Nylon or equivalent

d.) 1 Towing rope 20 m, 1/2” Nylon or similar

e.) 4 Fenders middle size

f.) Bow Thruster (optional)

7.5 STEERING

Steering system, hydraulic, for Stern Drive.

Steering system is for Stern drive single engine, single cylinder single station hydraulic steering system.

Steering installation should be in accordance with manufacturer’s instructions and generally comply with ISO 8848 Small craft – Remote steering systems.

Steering station is on steering console, located on center of driver cockpit. Visibility from steering position should match ISO 11591 Small craft, engine-driven – Field of vision from helm position

7.6 NAV. EQUIPMENT

a.) Magnetic compass 75-100 mm or similar, flush-mounted on the console.

b.) GPS with chart plotter, console mounted of 5 inches screen.

c.) Depth sounder/fish finder, console mounted.

d.)VHF marine radio.

e.) Marine binocular

f.) Installation and wiring of navigation equipment should be performed according to manufacturer’s specification.

Navigation equipment should be provided with splash proof closure, capable to be locked when at rest.

7.7 SAFETY EQUIPMENT

a.) 13 life vests of approved type, kept under sofas

b.) 1 life buoys, one installed in reach from steering station, port, another installed at swimming platform, starboard

c.) 1 hand hold flare, red color, SOLAS approved type.

d.) 1 parachute rockets, red color, SOLAS approved type.

e.) 1 smoke signals, orange color, SOLAS approved type .

f.) First aid kit

g.) Horn

8.SEA TRIALS

a.) Sea Trials are to be held before delivery, at or near the builder’s facility, at a time and location mutually agreeable to both the owner and/or his representative and to the builder.

b.) The hull and decks are to be carefully inspected for any leaks

c.) All underwater fittings and penetrations are to be individually inspected for leaks in both open and closed and/or operating and non operating condition

d.) All hatches, windows and doors are to be tested for watertightness, by direct spray all around with a hose at adequate pressure

e.) The vessel is to be thoroughly and systematically examined to ensure that all systems are in sound operating order.

f.) A flotation measurement and an inclining experiment are to be performed, as specified by the designer. If the designer cannot be present, then a written report will of the flotation and inclining experiment will be prepared by the builder and forward to the designer.

g.) Any defects or problems caused by faulty construction or installation, or by faulty machinery, equipment or hardware are to be corrected by the builder before delivery.

h.) Operation of all systems is to be checked at the dock, and then underway.

i.) A systematic, itemized written record of all systems checks is to made and a copy of this record delivered to the owner and to the designer.

j.) A full-power, cruising speed, and low speed run of not less than 20 minutes each shall be conducted during the trials.

k.) Low-speed maneuvering and backing tests are to be performed

l.) Turning maneuvers are to be conducted at all speeds

m.) A systematic, itemized written record of all sea trial test results and raw data are to be forwarded to the designer.

9.DELIVERY

a.) Before delivery, the entire vessel is to be cleaned thoroughly of all chips, shaving, sawdust, grease, scuff marks, or dirt of any kind.

b.) Any dirty or marked paint or varnish work is to be washed or refinished as required.

c.) Any chipped or damaged joinerwork is to be fully repaired

d.) All equipment furnished by the owner is to be installed properly or stowed aboard as required.

e.) The builder is to calibrate all machinery instruments, tank gauges, etc. before delivery.

f.) The vessel is to be delivered spotless and in mint showroom condition.

g.) The builder is to provide the owner with a well-organized set of all the manuals, warranties, and receipts for all equipment, and machinery installed.

h.) The builder is to provide the owner with schematics of all systems as built and installed: electric (12-volt and 220-volt); fresh, grey and black water; fuel system; bilge piping; firefighting. LPG system.

The builder is to provide the owner with all standard legal documents and paperwork required for: proof of ownership; registration; documentation; import and/or export; tax, insurance and banking requirements